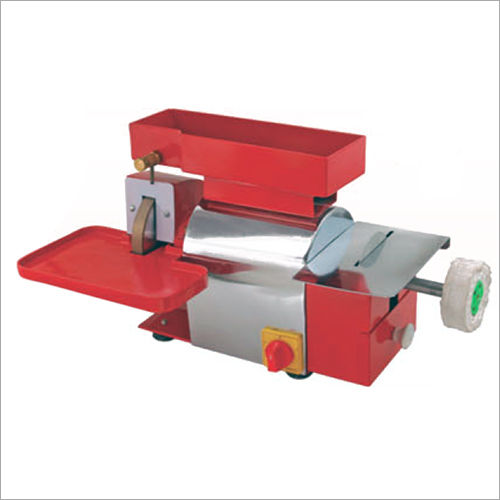

Optical Frame Lens Groover Machine

Optical Frame Lens Groover Machine Specification

- Theory

- Manual Mechanical Operation

- Accuracy

- High precision cutting for accurate lens grooving

- Lens

- Suitable for all types of optical lenses (plastic and glass)

- Color

- White and Black

- Measurement

- Manual adjustment with precision indicators

- Objective

- To create a precise groove on the lens for mounting

- Product Type

- Lens Groover Machine

- Material

- Metal and Plastic

- Size

- Compact tabletop design

- Weight

- Approx. 2.5 kg

- Length

- Approx. 22 cm

- Function

- Grooving optical lenses for rimless frame mounting

- Resolution

- Groove width adjustable from approx. 0.65 mm to 1.0 mm

- Maintenance

- Easy to clean and maintain

- Safety Features

- Protective lens cover reduces debris exposure

- Groove Depth Setting

- Adjustable depth control for customized grooves

- Applications

- For optical workshops, eyewear manufacturing, and repair

- Durability

- Corrosion-resistant materials ensure long-lasting performance

- Grooving Wheel

- Diamond-coated for smooth finish

- Power Requirement

- Not Required (fully manual)

- Suitable Lens Diameter

- From 18 mm up to 70 mm

- Operation Method

- Manual hand-operated lever

- Fixture Type

- Non-slip lens holding clamps

Optical Frame Lens Groover Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- Piece

- Delivery Time

- As per Location Days

- Main Domestic Market

- All India

About Optical Frame Lens Groover Machine

Managing with an aim to meet up with exact requirements of the customers, we are engaged in offering Optical Frame Lens Groover Machine. This machine is precisely manufactured at our unit, under the fruitful guidance and supervision of highly experienced and experienced professionals. Offered machine is used for processing half-frame glasses and rimless-frame glasses center curve, front curve and rear curve. The provided range of Optical Frame Lens Groover Machine is properly tested on several guidelines by our quality controller to provide defect free range at the customer's end.

Other Details

Power Source : Electric

Warranty : 1 Year

Features:Corrosion Resistance, Long Life

Delivery time depend on location

Precision Grooving Solutions for Every Lens

Achieve flawless grooves in optical lenses ranging from 18 mm to 70 mm using manually adjusted precision indicators and a diamond-coated wheel. This machine is engineered for rimless frame mounting and supports both plastic and glass lenses. Its adjustable depth setting caters to varied groove requirements, providing consistent results in every application.

Durable, Safe, and User-Friendly Design

Constructed from robust, corrosion-resistant materials, the groover combines a sturdy metal body with high-grade plastic components. Non-slip clamps secure lenses during operation, while the protective cover shields users from debris. The device is compact, weighing approximately 2.5 kg, and designed for easy maintenance and cleaning.

Ideal for Optical Workshops and Manufacturing

The manual hand-operated machine is perfectly suited for eyewear manufacturers, importers, exporters, and suppliers. Its energy-free operation and compact size make it suitable for tabletop use in busy optical workshops, providing reliable and accurate performance without the need for electricity.

FAQs of Optical Frame Lens Groover Machine:

Q: How do I adjust the groove depth on the Optical Frame Lens Groover Machine?

A: The groove depth can be adjusted manually by using the precision indicators provided on the machine. This feature allows users to customize groove depths for different lenses, ensuring a perfect fit for rimless frames.Q: What types of lenses are compatible with this groover machine?

A: This machine is suitable for all types of optical lenses, including both plastic and glass lenses, with diameters ranging from 18 mm to 70 mm.Q: Where can I use the Optical Frame Lens Groover Machine?

A: The machine is ideal for optical workshops, eyewear manufacturing units, and repair centers. Its compact tabletop design makes it easy to set up and use in various professional environments.Q: What are the safety features of the lens groover?

A: Safety is enhanced with a protective lens cover, which reduces exposure to debris during operation, and non-slip clamps, which securely hold the lens, minimizing risks while grooving.Q: How is the grooving process performed?

A: Grooving is done using a manual hand-operated lever that rotates a diamond-coated wheel. The lens is firmly held by non-slip clamps, and users can set the groove width between approximately 0.65 mm to 1.0 mm for precise mounting.Q: What maintenance does the groover machine require?

A: Maintenance is straightforwardsimply wipe the machine and its components to remove dust and debris. The groover is constructed with corrosion-resistant materials, making it easy to clean and maintain over time.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

|

VED ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry